5G Network Slicing & Splicing for Industry 4.0 Use Cases

Introduction to Zeetta Networks

Hema Kadia – Welcome Vas, appreciate if you can introduce us to Zeetta Networks.

Vassilis Seferidis – Hema, thank you for inviting us and presenting the use cases for the industry 4.0 and obviously what we are doing in the UK and especially in this particular deployment for 5G in industry 4.0 context.

Zeetta Networks is a spin out from the University of Bristol, who have been operating for the last five years. And the focus is very much about network automation, especially applied in enterprise networks. And increasingly in private 5G networks. The company developed software tools that simplify their network operations, and make it as easy to deploy private 5G networks as it is to deploy a Wi Fi network.

What is Network Slicing?

Hema Kadia – We would like understand what exactly is network slicing?

Vassilis Seferidis – Network slicing must be quite familiar to a lot of your audience. It is basically the definition of an overlay network, a virtual network, basically a logical network that can be isolated and provides basically the actualization of a use case, a user group, or a user devices that you want to isolate and deliver a special service to them.

The typical example in the 5G environment is when you want to isolate, you know, the low latency applications, for example, from all the other applications. And then you isolate these low latency applications in a special sort of construction, logical networks, we call network slices. The importance of that, is that, obviously, make the whole utilization of the network more efficient because you use the common physical infrastructure. Those are logical networks that run on top of the common infrastructure, which makes the use of the network even more efficient.

What is Network Splicing?

Hema Kadia – Appreciate if you can please explain what is is network splicing, the term coined by Zeetta Networks.

Vassilis Seferidis – Network Splicing a very important use case for the 5G encode. Network splicing is all about combining if you like, or joining network slices that you have created in the previous of, in the physical infrastructure, in order to actually provide end to end services across different domains. And what we do basically here is that that we combine if you like the bytes of connectivity to the network slices, and you will combine them to actually provide them a more consistent 5G service across end to end.

Industry 4.0 Use Cases for 5G-Encode Project

Hema Kadia – Zeetta Networks has been leading the Industry 4.o use cases for the 5G ENCODE project. What are the Industry 4.0 5G use cases that you are working on and how are you leveraging both network slicing as well as network splicing for supporting these use cases.

In-factory and In-Transit Asset Tracking | Network Slicing & Splicing

Vassilis Seferidis – Sure. I think the applications actually makes and brings the network splicing and slicing in prominence, I guess, is the one on the left side, which is all about the in-factory and in-transit asset tracking, okay. Obviously, I guess most people understand that in-factory asset tracking.

Here is the potential basically to track different assets within the factory as they move around the factory, the factory floor. You want to actually locate them wherever they are. In this particular case, in the deployment we have in them in the 5G Encode project.

The deployment is in the National Composite Center (NCC), where the assets are basically chemical. They have a very limited time life cycle. So they have to be used within an hour or few hours. Which means that you have to track them to know what exactly they are as they move around the factory floor. So they can be used within the time limits that you have and they have to be monitored continuously throughout the sort of journey from, you know, the creation of the moment they arrived from your factory door, until they’re used by the machines within the NCC.

Now, this is obviously to improve productivity and because you know, and you don’t waste time to find the resources, that also obviously to you know, to know where exactly things are right, you know, like a better maintenance of in use cost. The more important thing and for the network, slice and splice comes into play is that we can allocate, of course, a dedicated network to actually track the assets as they move around the factory that’s within the factory.

The network splicing comes to play when you want to combine and you want to track the assets as they move through the factory and they go to another factory across the city, then they have to actually start the journey from one private network which we deploy in one location to the public network from a operator like Telefonica, in this case, and to another private network from the other factory.

What we have then is you want to actually create slices in the factory, the originator factory, you want to create a slice within the public network, Telefonica in this case, and you want to create a slice in the destination factory, and you want to have a jointly to join all these slices, the independent slices to become a seamless transition of your service from one private to public and the private network.

The use case of in transit the asset tracking that is very important for this particular network and the implementation will have been this project, but very important for logistics applications as well.

Closed loop manufacturing in Liquid Resin Infusion (LRI) | Network Slicing & Splicing

Hema Kadia – Can you also elaborate on the use case of closed loop manufacturing?

Vassilis Seferidis – So this is a very much an ultra low latency application. I’ll explain what we’re actually doing here. There is the same machine on the factory floor which is called liquid resin infusion. This is all about stuff in applying resins which are basically chemicals something like a glue I guess to structures that they can be named like skeletons which are basically things like a sort of plane wings and you know, chassis for cars and things like that. So quite a big list of constructions.

So the manufacturer will be preparing that and they will apply resin, in such a way that actually stuff pumps the resins from one point and then sucks from the other with a vacuum sort of machinery. The process is very time consuming. So do take some time to actually complete. But it’s also very, very delicate in the sense that you have to monitor the process because they can be like stuff, errors all around the place. Quite a lot of expertise. So, and, and human expertise, just because of that, they won’t automate this process.

If you just give you an example, if you just make a mistake, that can translate to maybe 50,000 pounds of cost, right, because you just get to throw away the whole plane wing, because that’s the prototype you’re building there, right. In that case, you want to want to the process as it happens in real time, ideally. What they have today is they have about 10 sensors monitoring the process, which takes usually a couple of hours and they adjust basically the application of resin as it goes. The problem they have is that them in order to make this process more precise, and more, you know, error free if you like, so they can read them, you know, correct.

You know, they can the benefits of prototype, the first time round, they’re going to introduce more sensors, they’re going to go to 100 or 200 sensors. Now the existing sensors are connected with them, you know that there’s the data collection machine, the server through these kinds of cables, you know, Ethernet cables, basically. And of course, moving to 100 to 200s of units, introduces element of scalability. We don’t have enough to cable structural you manage there there, I don’t have enough space to manage this complexity. And that’s why they will start thinking about the wireless, they can still use some wireless technologies existing in the in the moment you know, the Wi Fi for example. But that doesn’t allow you to, Wi Fi doesn’t allow you to actually control the network to the level that you want, with a very low latency. Just give an example, they want to collect all this data, processed them.

And of course, develop the loop the feedback loop to the applications within five milliseconds. So in order to do that, then obviously, the wild solution is the best in terms of actual latency, but the Wi Fi solution has to provide similar type of speed, right? You know, and that’s where they came to the mobile stuff environment, a private mobile, sort of deployment, so they can control this parametes in most detailed environment, right, and more precisely, and so that’s what we’re doing for them. Now, as I mentioned, just by doing this process, in, you know, improving the productivity of that and using the yield, you can actually save, you know, hundreds of thousands of dollars in in the factory.

How is network slicing done across fiber, mmWave & Telefonica’s 5G public network, for the Industry 4.0 use cases?

Hema Kadia – How are you doing the network slices across 3 networks – fiber network, mmWave network & Telefonica’s 5G public network, for the industry 4.0 use cases?

Vassilis Seferidis – Yeah, I mean, we have a slide here when there’s a small animation that actually provides some bit more detail of what we’re doing here. So have three locations: the NCC is the National composite center headquarters, the NCC filton is another location of the same company, which is maybe about six miles away. And then we have of course, the Millennium square, which is another sort of deployment of the universities, the University Bristol’s deployment of the private network, once again in the center of the city.

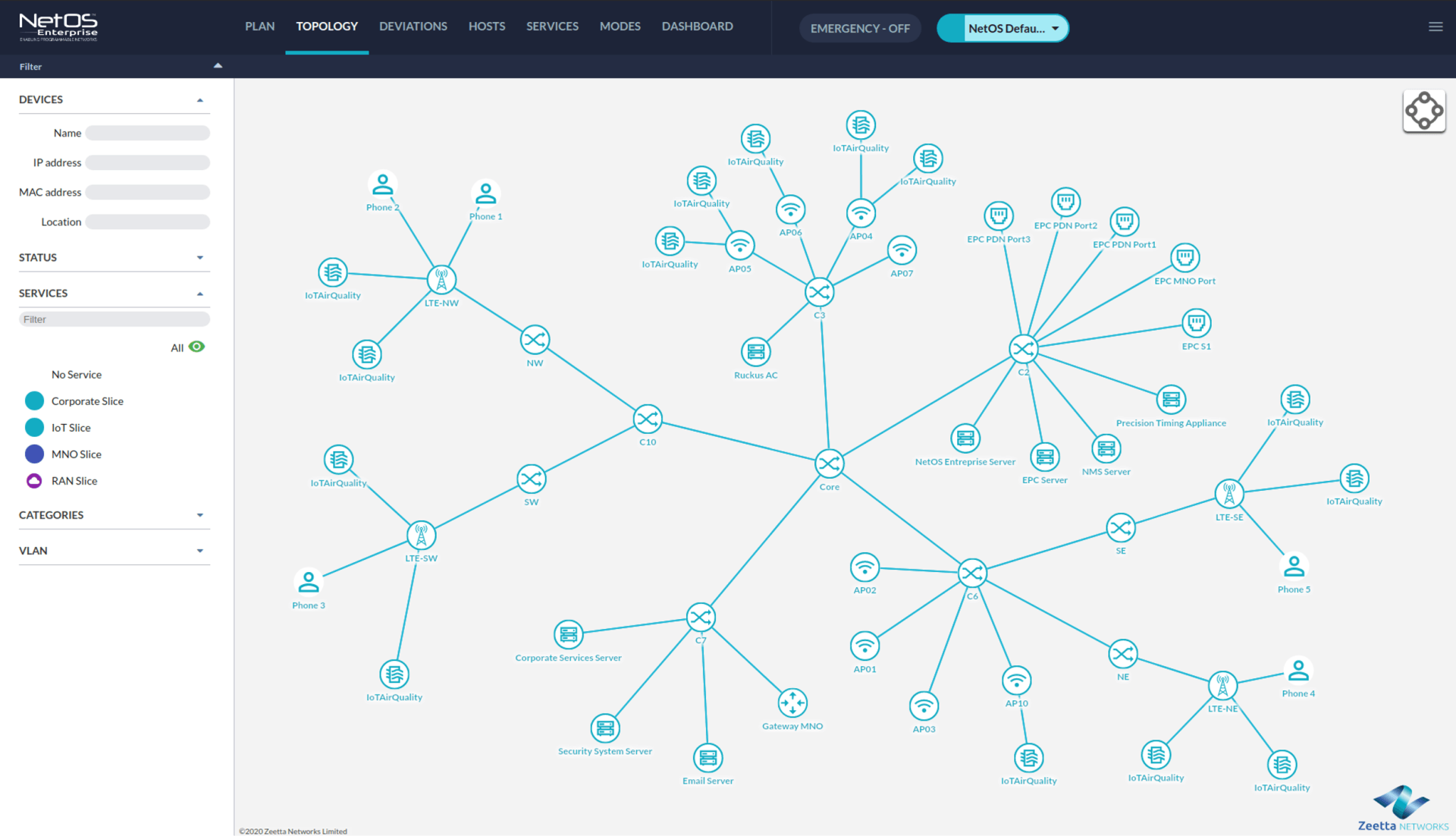

Now, these three locations have each one of those their own private network. So you have like, obviously, they run the 5g core, and the MEC, all in one location. Right. So it’s like a self contained environment. Yes, the black box you can see there is basically Zeetta’s technology, what we call NetOS Rapide, which allows us to do the slicing of this access network of the independence of the private networks.

So we’re able within this, each one of these environments to define types of connectivity from an access point, like in this case, it’s more cell from RAN to the MEC and to the Core through the core to an access point, right. And we do that in each one of those locations. Now, these locations are connected with each other with three different types of networks.

Obviously, you have the public 5g network from Telefonica, connecting the whole city and of course, the locations of NCC headquarter center and Millennium square. You have a millimeter wave network, which is basically connecting a 60 gigahertz network connecting the NCC headquarters with the other location of NCC Filton and you have the fiber network connecting the NCC filton with the Millennium square.

Each one of those transport networks is sliceable as well. Or obviously the Telefonica network is sliceable by Telefonica, its own stuff slicing technology and slicing the core. The millimeter wave exam is controlled by NCC, so it’s sliceable and we can have access to that and you can slice it and the optical network is the same thing that belongs to the university. And it is also a slice a fiber network in the optical layer. So our multi domain orchestrator, what you see that is a blue box is a software layer, allowing us to create slices in each one of these individual locations, but also create slices on transport networks as well.

And more importantly, once you have created these slices, obviously, you know, you can actually join these slices with the process that we call network splicing. So you have just joining the different slices, if you press probably the, the guys can actually see the farm there. Those are the slices that you can create in the transport network, and then the yellow, sort of the circles represent the splicing of that where you can actually combine now, the slice of the different transport networks with the local area networks, for the end to end delivery of service.

And all these slices, of course, are dependent on the use cases that you want to support. You know, if there’s a low latency application, you can create a slice in the local, sort of in the private network, which is a low latency, you know, three, five milliseconds, you request a similar slice from the Telefonica network. Obviously, you know, delivered in a way of API’s and hooks there and provide to them and then you have another set of slices from the other private network in the Millennium square to complete the end to end to slice with this special KPIs.

How are you managing orchestrator interoperatility across multi-domain networks?

Hema Kadia – The orchestrator will need to interface with different orchestrators or SDN controllers or legacy ecosystem application in different enterprises | telecom operator ecosystem. How are you managing this complexity in context of network slicing?

Vassilis Seferidis – Our technologies very much software defined networking technology so that is vendor agnostic and technology agnostic that means that we can actually slice any type of network you know from the transport network, the fiber network we discussed earlier, and millimeter wave to plan and sort of any kind off network and obviously software interface with any of the vendors. So it’s basically a software defined network technology, which should be, you know, supporting disaggregate solutions and able to support the different services.

What are the key technologies & products leveraged for network slicing?

Hema Kadia – What are the key technologies and the products that you’re leveraging both Zeetta’s network as well as there are some partners that are involved in this 5g ENCODE project?

Vassilis Seferidis – Yes, I mean, as mentioned earlier the networks are a big box, you know, we are presenting each one of those locations with a black square, it is basically a deployable version of our NetOS SDN controller.

And our SDN controller is basically an Open Daylight deployment. And a special version of the opendaylight controller, as the sdn controller which has been augmented with a lot of orchestration tools and extensions, which support different types of devices. That allows us to actually, as I mentioned earlier, slice the network, the private network in one location in one domain, and allow you to actually define types of connectivity VLANs, you know, the level of slices that you want to create in a single domain and software environment.

The NetOS Rapide is the deployable version of that, it is basically a box that will actually bring it to a factory and provide you with this capability. It’s a it’s a pop up network, if you like that actually provide you this kind of control and slicing capability. Our network splicer or NetSplicer is all about splicing, the different domains.

So you create basically the individual networks slices in each individual domain and the network splicer is actually combining or you can call it basically multi domain orchestrator for a better word, which basically combines the slices and makes it you know, the control and orchestration of your network end to end.

For us orchestration of the network is all about managing slices. So everything in the network is a slice and the service you provide is a slice and you just managing different slices with Orchestrator in a single domain with NetOS or with the NetSplicer, which is like the multidomain orchestrator.

Beyond Industry 4.0, what other use cases you are supporting via Network Slicing & Splicing?

Hema Kadia – What are the other use cases where you’re leveraging network slicing and splicing ?

Vassilis Seferidis – Sure. I mean, we have been involved some other interesting projects, applying the same basic technolgogy in areas like logistics, for example, entertainment. Logistics is very much similar to what I was describing earlier about asset tracking, you know, you have the asset and you want to target across different private and public networks. It is a typical use case for logistics are the firm environment.

And you have, of course, the other very interesting stuff, deployment for us is the smart venues, places you want to actually automate a lot of functions, you want to specify new services and deploy different services, but also have the network automation to simplify this kind of deployment. And what we call mode management, moving from one configuration of the network in your venue to another one with the press of a button.

It is very useful for venues for example, that they have their multi purpose for example, I’ll give you an example of that we have implemented in a stadium, the stadium can be used as obviously a sports venue, but they’re increasingly used as hospitality, you know, for wedding receptions and, you know, hospital, concerts, you know, conferences, you know, say industry events in their lives. So moving from one style of configuration, one mode of configuration to another with the press of a button, reconfiguring the whole network in one go, is what we can offer with that right and didn’t even know that through network slicing and splicing in the enterprise environment. So that we see as another application for the 5g as we move to the 5g and move away, to do to apply the same technology in kind of, you know, hospitality, if you like, or multi venue, smart venues, smart buildings, smart cities to the environment.

Vassilis Seferidis

CEO & Co-Founder of Zeetta Networks

Vassilis is CEO and Founder of Zeetta Networks an innovative spin-out company offering Open Networking solutions that monitor, optimise and automate the operations of complex ICT networks to extract greater efficiency and agility while enhancing the end-user experience and reduce the overall networking costs. Vassilis has more than 25 years’ experience in the Telecommunications, Entertainment and Consumer Electronics industry.

Before founding Zeetta Networks, Vassilis was VP of Business Development for Samsung Electronics responsible for driving revenue growth and strategic development of Samsung’s Smart TV (OTT) business in Europe. Prior to Samsung, he held executive management positions at British Telecom, Toshiba, Philips, QIO Systems and British Standards Institute. Vassilis holds a BSc and MSc from Aristotle University of Thessaloniki, Greece, a PhD from Essex University, UK and an MBA from Cass Business School (University of London).

In 2011 Vassilis has been included in the Euro50 list of the 50 most influential people in the Broadcasting and Telecommunications industries in Europe:

http://www.digitaltveurope.net/20617/the-euro50-qa-vassilis-seferidis-samsung/