Hyperconnected, productive and efficient: how 5G will build a more resilient manufacturing industry

Vassilis Seferidis, CEO and Founder of Zeetta Networks

Original source: https://www.theengineer.co.uk/comment-5g-manufacturing-resilience/

Manufacturing plays a critical role in the UK economy. The industry makes up 11% of Gross Value Added (GVA), 44% of total UK exports, and directly employs 2.6 million people. It is, however, a sector that has had to navigate a vast range of challenges over the past few years, including socioeconomic turbulence, lockdowns, impending decisions around trade deals with Europe and the potential impact on supply chains.

Amidst such uncertainty there is one thing that remains clear: manufacturers face a time of inevitable change at every level of their business. And it is how this change is embraced that will ultimately determine the winners from the losers.

The application of 5G technology has the power to drive positive change across almost every industry in the world. For manufacturing in particular, 5G promises a host of benefits. From improving efficiencies to boosting output, harnessing this technology will prove truly transformational.

Smart factories: remote connectivity and business resilience

The introduction of private 5G networks in manufacturing enables the creation of smart factories. The level of automation permitted by smart factories promises a host of benefits, including real-time linkages to customer demand forecasts, reliable quality, predictable production capacity and lower cost of production. The heightened visibility, pace of production and efficiency allowed by smart factories are key drivers that contribute to driving higher productivity levels in manufacturing.

In lockdown environments, where businesses are forced to adopt remote operating models, 5G can prove a valuable ally when it comes to business resilience. With its low latency, reliable connectivity and high speeds, 5G allows employees to connect in real-time from remote locations. For example, 5G-powered virtual reality could be used to connect an onsite engineer with a colleague working from home, allowing them to collaborate and work closely together without the need for them to be physically close.

The path to a hyperconnected future

Connectivity alone can only take us so far, but the combination of universal connectivity and intelligence is dynamite. This is hyperconnectivity, or the Internet of Things (IoT), and it is what 5G will enable. In a hyperconnected environment, everything is communicating - machine to machine, machine to person and person to person. These interactions are conducted both one to one and one to many, meaning that vast amounts of data and information are being communicated in real-time via a highly secure 5G network.

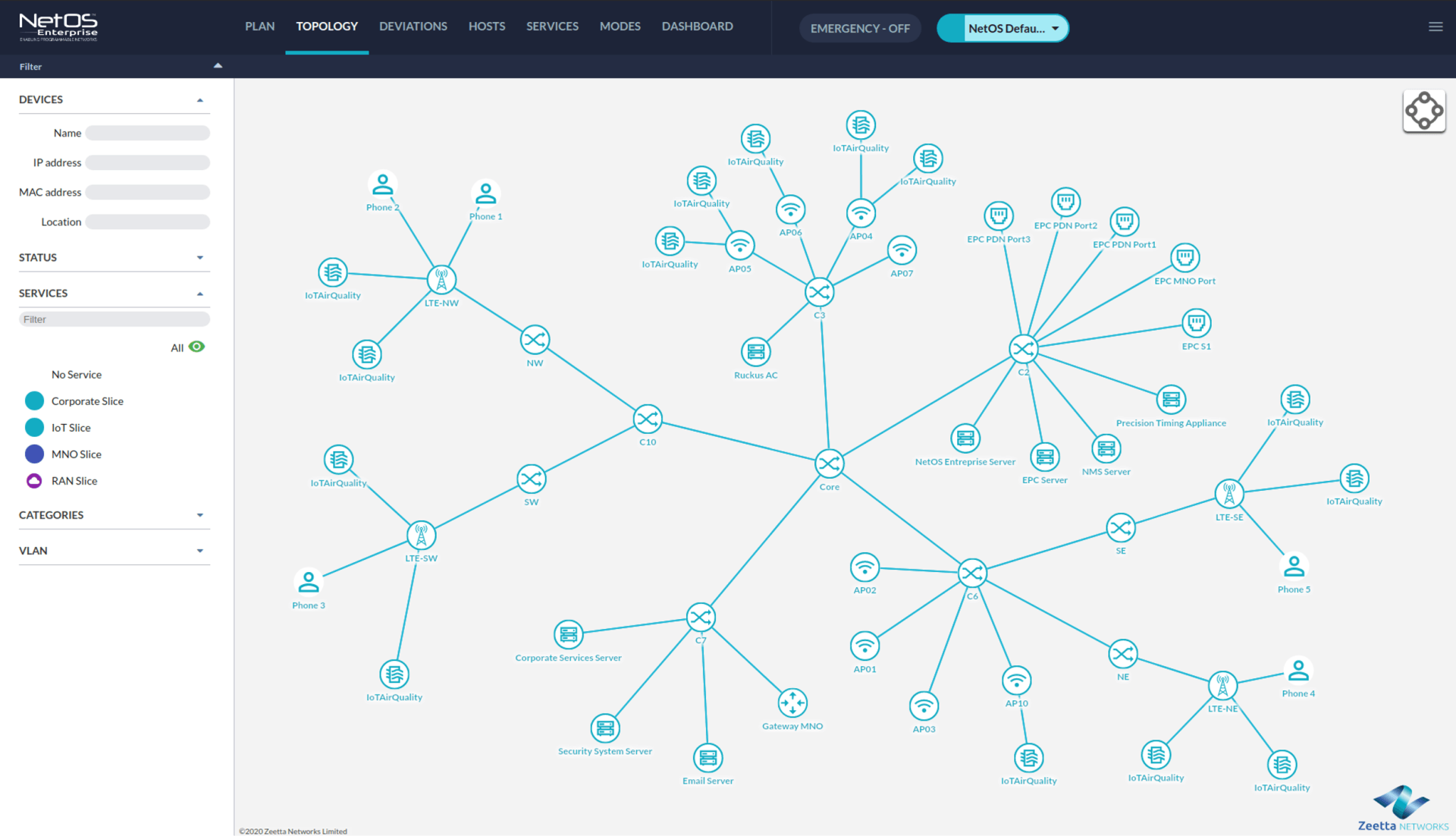

The level of hyperconnectivity provided by 5G supports network slicing and splicing, which enables enterprises to create networks customised to specific needs. Network slicing and splicing enables private 5G networks to interact with public and other private networks outside of the enterprise environment. This ensures only the correct level of connectivity is allocated to each user or device, therefore optimising performance and creating cost savings. Within a factory, for example, multiple different types of production equipment all require different levels of connectivity and varied degrees of latency and throughput.

What’s more, at a time when travel and physical interactions are limited, hyperconnectivity opens the door to a more globalised, efficient and less wasteful manufacturing ecosystem. Global supply chains, for example, will operate more efficiently, with high-value assets being able to be tracked from a remote location in real time. Furthermore, with machines able to alert workers to faults before they have a chance to become an issue, workplaces will be safer and more reliable.

From concept to reality

Already, we know that 94% of manufacturers are adjusting their business in new ways to achieve growth. This is a huge step in the right direction and it is heartening to see such a unanimous appetite for transformation. But how do we convert this appetite into network deployments in factory settings?

The answer is simple: we must develop clear business cases and compelling value propositions that prove to manufacturers how transformative this technology is, and specifically what it can do for their business.

Until recently, 5G trials have been centred around uncovering the potential benefits of 5G in industrial settings. For example, trials at the Worcestershire 5G Testbed found that 5G could boost productivity by as much as 2%, the equivalent of a £2.6 billion increase when rolled out on a national level.

The focus of trials has now shifted. Now, projects like 5G-ENCODE, part of the government’s £200 million 5G Testbeds and Trials Programme, have been set up to demonstrate exactly how 5G can be applied to solve specific problems in an industrial setting.

Led by Zeetta Networks, the 5G-ENCODE project will see a private 5G network built at the National Composite Centre in Bristol. The network will be used to explore new business models and test manufacturing use cases, including augmented reality / virtual reality to support design, manufacturing and training; monitoring and tracking of time sensitive assets and wireless real-time in-process monitoring and analytics.

Results and learnings from the project will be used to demonstrate exactly how 5G can be applied to solve specific problems in an industrial setting. This insight will prove critical in helping to build the reliable, effective business model of the future. While projects like 5G-ENCODE may focus on a particular industry, the business models created will be applicable to a number of other sectors. In the case of 5G-ENCODE, this extends beyond manufacturing to include hospitals, stadiums, offices and other venues which can all benefit from next-generation networks.

Hailing the industry of tomorrow

There is no denying that the operating environment for manufacturers today is tough. But, in somewhat serendipitous timing, these challenges present themselves just as new technologies are beginning to gain real momentum.

5G is not the silver bullet, but it is a guiding light towards a more connected and productive future. Private 5G networks will hail an era of hyperconnectivity, and the opportunities that this will bring to businesses are truly immense. Today, we find ourselves at a turning point in history. I call on manufacturers large and small to be bold, to embrace new technologies and reap the benefits it will bring.