Blog Layout

Interview with Vassilis Seferidis, Co-founder at Zeetta Networks

Dec 14, 2020

Interview with Vassilis Seferidis, Co-founder at Zeetta Networks: A Leading Partner of 5G-ENCODE

5G-ENCODE is a pioneering project looking to make the benefits of 5G technology a reality for UK manufacturers. The project is one of the UK government’s biggest investments in 5G for manufacturing to date and has been set up to establish clear business cases and value propositions for the application of 5G technology in manufacturing.

Led by Zeetta Networks, activity started in early 2020 and will run until March 2022. The key objective is to design and deliver a private 5G network within the National Composites Centre. This will be used to explore new business models and 5G technologies, including network slicing and splicing, within an industrial environment. Specifically, activity will focus on three areas:

- AR/VR to support design, manufacturing and training

- Monitoring and tracking of time sensitive assets

- Wireless real-time in-process monitoring and analytics

These use cases will be sector agnostic and will be deployed across a range of industries enabling new business models and opportunities, streamlining operations and creating additional revenue streams. This is especially important as the nation navigates economic turbulence brought about by the Covid-19 pandemic.

How and why was 5G-ENCODE founded?

Across the UK, businesses from almost every sector are looking to digital transformation as a way to enhance productivity and efficiency. A core part of digital transformation is the application of new networking technologies to revolutionise existing processes. In manufacturing, the use of 5G to automate and streamline processes will dramatically increase output and drive efficiencies. The 5G-ENCODE project is the next step in our journey to digital transformation, and will test the real-life use cases for 5G technology.

Moreover, use of new, more energy efficient communications technologies like 5G, are expected to have a substantial environmental impact at both national and global levels. Indeed, research by O2, a 5G-ENCODE partner, found that 5G will facilitate greater flexibility, lower costs and shorter lead times for factory floor production that together could take up to 40 Megatonnes of carbon out of the economy by 2035.

It is only through projects like 5G-ENCODE that are committed to building and testing these realistic yet challenging use cases that we will establish clear, compelling value propositions for 5G in industry.

I’ll pass you onto Marc Funnel Head of Digital, National Composites Centre to talk more about how we’ve evolved and what we have planned for the future…

How has the need for 5G-ENCODE evolved during the pandemic?

[Marc Funnel] Covid-19 has enabled us to initiate a smarter way of working that ensures we can operate virtually, streamlining the way we work. It has significantly highlighted the need for 5G use cases, especially those around virtualisation and the ability to use immersive technologies such as AR/VR and 360-degree training scenarios. It has expanded the collaborative reach for our internal and external contractors, improving remote access solutions and potential engagement on the test bed. It has resulted in interest from schools and universities, who want to learn about the immersive classroom use case that we are promoting as part of 5G-ENCODE and the Digital Engineering Technology & Innovation (DETI) programme.

What can we hope to see from 5G-ENCODE in the future?

[Marc Funnel] 5G-ENCODE achieved successful implementation of the first phase of the programme, a 4G network, which will set the baseline for the 5G network. We’re engaging with small cell 5G vendors and smart cell technology providers to implement the 5G demonstrator testbed. In parallel with this, we’re inviting technical providers and industry partners interested in using the test bed to explore this with us through UK government funding that is available. This will expand the range of use cases in phase 2 (June 2021- April 2022) of the project which will show the benefits that 5G can offer over 4G, and further explore expanding these use cases to enhance the innovation scope of the programme. We’re engaged with a local research initiative in the West of England, investigating further a haptic interface with robotics solution.

What are the benefits to 5G over 4G and Wi-Fi, particularly within the manufacturing industry?

[Vassilis Seferidis] 5G has the potential to be truly transformational within the manufacturing industry. Machine to machine connectivity, ultra-low latency and unique network slicing capabilities will transform traditional manufacturing processes, making them more efficient and productive.

Unlike 4G and Wi-Fi, 5G is designed from the ground up to be completely secure end-to-end. Not only this, but 5G is highly scalable in a way that other technologies are not. Its wireless nature means that mission-critical availability can be deployed rapidly across a given environment, with minimal waste and maximum performance.

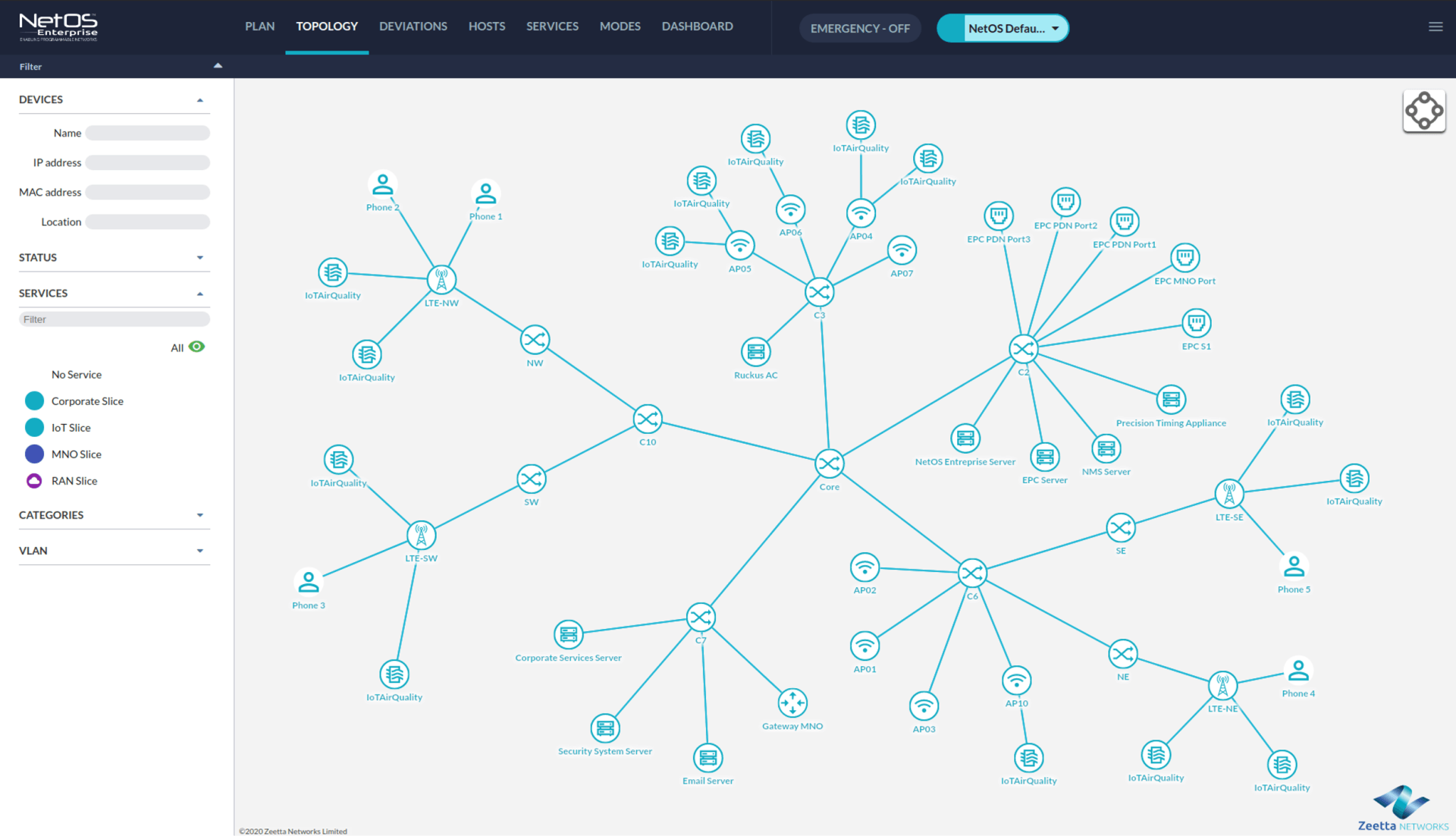

One of the most innovative benefits of private 5G networks is their slicing and splicing ability which can hugely improve business efficiency. A key focus of the trials at 5G-ENCODE will demonstrate the efficacy of ‘network slicing and splicing’ in industrial settings. These technologies deliver a customised network that meets business demands. They allow operators to either create multiple virtual networks that can be customised and optimised for the specific service and traffic levels needed (network slicing) or combine two or more sub-networks to create a new ‘aggregated network topology’ (network splicing).

Of course, these technologies can be used not only in industrial private 5G networks but also can be deployed across a vast range of industries, from healthcare and manufacturing to transport and entertainment.

by websitebuilder-hub

•

23 Oct, 2020

5G-ENCODE switches on the first phase of its network at the National Composites Centre. This will test existing technologies and provide a baseline against which the 5G network capabilities will be compared. The project will establish and test 5G use cases to make the benefits of 5G a reality for UK manufacturers. London, 22nd October 2020: Today, 5G-ENCODE, a pioneering project that aims to make the benefits of 5G a reality for UK manufacturers, announces the switch on of its Phase One Industrial Private 4G Network at the world leading National Composites Centre (NCC), to establish a baseline for existing technology. This comes ahead of its Phase Two Industrial Private 5G Network, which will go live in 2021. The Phase One 4G network has been designed and developed by leading partners, Zeetta Networks and the University of Bristol’s Smart Internet Lab, and installed at the National Composites Centre. It will be used to establish a baseline for existing cellular technologies, against which results from the private 5G network, which will be installed in Phase Two of the project, can be benchmarked. The goal is to prove the value of 5G for use case performance and user experience and demonstrate the extent to which businesses will get a real return on investment from deploying private cellular networks within manufacturing. 5G-ENCODE is part of the Department for Digital, Culture, Media and Sport’s (DCMS) 5G Testbeds and Trials Programme and is one of the UK government’s biggest investments in 5G for manufacturing to date. New technologies, particularly 5G, hold the key to unlocking significant benefits for manufacturers, including streamlining operations and increasing productivity. The project has been set up to establish clear business cases and value propositions for the application of 5G technology in manufacturing. The cellular network will be used to explore new business models and 5G technologies, including network slicing and splicing, within an industrial environment. Specifically, activity will focus on three areas: Augmented Reality / Virtual Reality (AR/VR) to support design, manufacturing and training. Monitoring and tracking of time sensitive assets. Wireless real-time in-process monitoring and analytics. In the Phase One 4G Network, the focus will be on testing the asset tracking and AR / VR use cases. Each use case will be tested and data gathered on network performance, user experience and business benefit realisation. This process will be repeated for the Phase Two 5G Network and the data between 4G and 5G will be compared and analysed. Vassilis Seferidis, co-founder and CEO at Zeetta Networks says: “Zeetta Networks is proud to be the leading partner for the 5G-ENCODE project. The use cases being explored will be integral to accelerating Industry 4.0. Phase One is just the beginning, and we’re confident that this project will be key to revitalising the UK’s manufacturing industry and safeguarding it against the next global recession”. Marc Funnell, Head of Digital, and Director of DETI, National Composites Centre, says: “As a world-class research centre, the NCC is delighted to be the industrial test bed for the 5G-ENCODE consortium of leading industrial innovators. Today’s announcement marks the start of this project delivering real-life impact through the development of specific use cases for the 5G-ENCODE and Digital Engineering Technology & Innovation (DETI). We look forward to testing and sharing the results”. Xavier Priem, Senior Research Fellow at Smart Internet Lab says: “Smart Internet Lab is proud to support and provide expertise to the 5G-ENCODE consortium. We are delighted to be working alongside communities, telecom and Industry 4.0 experts in this project by providing knowledge on 4G & 5G technologies on the delivery of use cases. Our work will be fundamental in introducing new capabilities into Industry 4.0 processes and systems which will provide more flexibility.” --ENDS-- About 5G-ENCODE 5G-ENCODE is a £9 million collaborative project aiming to develop clear business cases and value propositions for 5G applications in manufacturing. The project is partially funded by the Department for Digital, Culture, Media and Sport of the UK Government as part of its 5G Testbeds and Trials Programme. It is run by a consortium of nine partners: Zeetta Networks, National Composites Centre, Mativision, Plataine, Solvay, Toshiba, Telefonica, Siemens and the University of Bristol’s Smart Internet Lab. https://www.5gencode.com Download

by websitebuilder-hub

•

10 Sept, 2020

The manufacturing industry has suffered particularly, with many manufacturers still operating at between 25% and 50% of normal levels. As the industry starts to get back on its feet, it is time to focus our attention on how we can use this as an opportunity to rebuild even stronger. Technology, specifically private 5G networks, have the opportunity to play a critical role in the recovery of the manufacturing sector. At O2, we want to be part of this rebuilding process. That is why, through the DCMS-funded 5G-ENCODE project, we are helping to build a 5G-powered smart factory. Working with partners including Zeetta Networks, Siemens and Toshiba, the project will create clear use cases that demonstrate the power of private mobile networks to help businesses build back better. A key focus of the trials at 5G-ENCODE will be ‘network slicing’ in industrial settings. Network slicing gives manufacturers the capability to divide the private 5G network in line with demands of particular users and applications. But what does this mean in reality? In short, it means that systems will operate more efficiently and resource allocated where it is needed rather than wasted. As a result, system output will improve and cost of ownership of assets will reduce. Private mobile networks present one of the most exciting opportunities for UK industry. They deliver highly secure, ultra-reliable connectivity that allows for the automation of a number of business processes. Not only does this dramatically enhance productivity, but the use of Automated Intelligence (AI) also makes workplaces safer by alerting workers to faults before they have a chance to become an issue. At O2, we are invested in rebuilding Britain. A core part of this is finding new ways to use technology, specifically 5G, to drive efficiencies. That is why we continue to invest in projects and initiatives that explore exactly this. For example, we recently set up a private 5G network for Northumbrian Water Group. The connectivity provided by the network meant that experienced technicians could remotely guide on-the-ground teams through complex tasks by relaying real-time infrastructure data and instructions. Not only did this dramatically improve communication within the business, it also boosted productivity. Private mobile networks will be truly transformational for manufacturers. They offer a unique opportunity to build a more resilient, safer and environmentally friendly business. Interested in taking advantage of the latest 5G technologies? Get in touch to see how we could work together.