Blog Layout

5G will transform manufacturing – despite coronavirus delays

Jun 23, 2020

Covid-19 may have led to a hiatus in the 5G roll-out, but smart factories are still driving the sector’s race to adopt next-generation connectivity.

5G is the much-feted low-latency mobile network that is billed to revolutionise industries and expedite the automation age. Although it’s already managed to inflame the anxieties of some conspiracy theorists who say it’s responsible for the coronavirus pandemic, the technology is still in its infancy. One of the sectors racing at the forefront to adopt it, however, is manufacturing.

ABI Research predicts that by 2028, manufacturing will make up nearly a quarter

of the total revenue in the 5G “ultra low-latency use cases” market – where applications must be close to real-time. Barclays estimates that widespread adoption in UK manufacturing could add £2bn in revenue to the sector within five years.

Smart factories that incorporate Internet of Things (IoT) devices, sensors and automation are driving the sector’s need for next-generation connectivity. The technology will allow factories to dispense with floor-clogging ethernet cables, and increase the adoption of wireless machines connected directly to the cloud. The stability and speed of 5G is becoming essential for processing ever-multiplying data streams. In turn, the increased volume of data produced in smart factories can feed into AI systems that more effectively streamline all of the site’s activities.

Research firm IHS Markit predicts that by 2025, more than 75 billion IoT devices will be installed in the manufacturing sector. According to a report from McKinsey, this will create up to $3.7trn of annual economic impact for smart factories.

“Everything relies on connectivity from the robots to sensors – connectivity is such an important part,” says Detlef Zühlke, a German engineer described as the “spiritual father” of the smart factory. “So the network is an important part of enabling the digital transformation of the factory. What we call industry 4.0.” Industry 4.0 is the term used to capture this emergent stage of industrial production.

But in terms of adoption rate, Covid-19 has thrown a spanner in the works. As with practically every other area of industry, the progression of 5G has been impacted by the global pandemic. The EU had previously told member states they must take “concrete and measurable steps” to implement 5G by 30 June. This has now been postponed.

5G spectrum auctions were due to take place across much of Europe in spring 2020, but many have instead been suspended indefinitely, including in France and Spain. China, which suffered a setback due to coronavirus, has redoubled its efforts to get its 5G roll-out back on track, something President Xi Jinping considers a way to mitigate the economic fallout from Covid-19.

The UK’s own progress could be further hindered by the ongoing ruckus over what role Huawei – the global leader in 5G – should play in Britain’s network. Ministers initially said that its role would be restricted to 35 per cent, after the US claimed the Chinese company posed a national security risk. However, Prime Minister Boris Johnson has reportedly

instructed officials to draw up plans to reduce China’s involvement in the UK’s infrastructure to zero by 2023. This is despite the fact that the UK’s security agencies have said they don’t believe there is a risk.

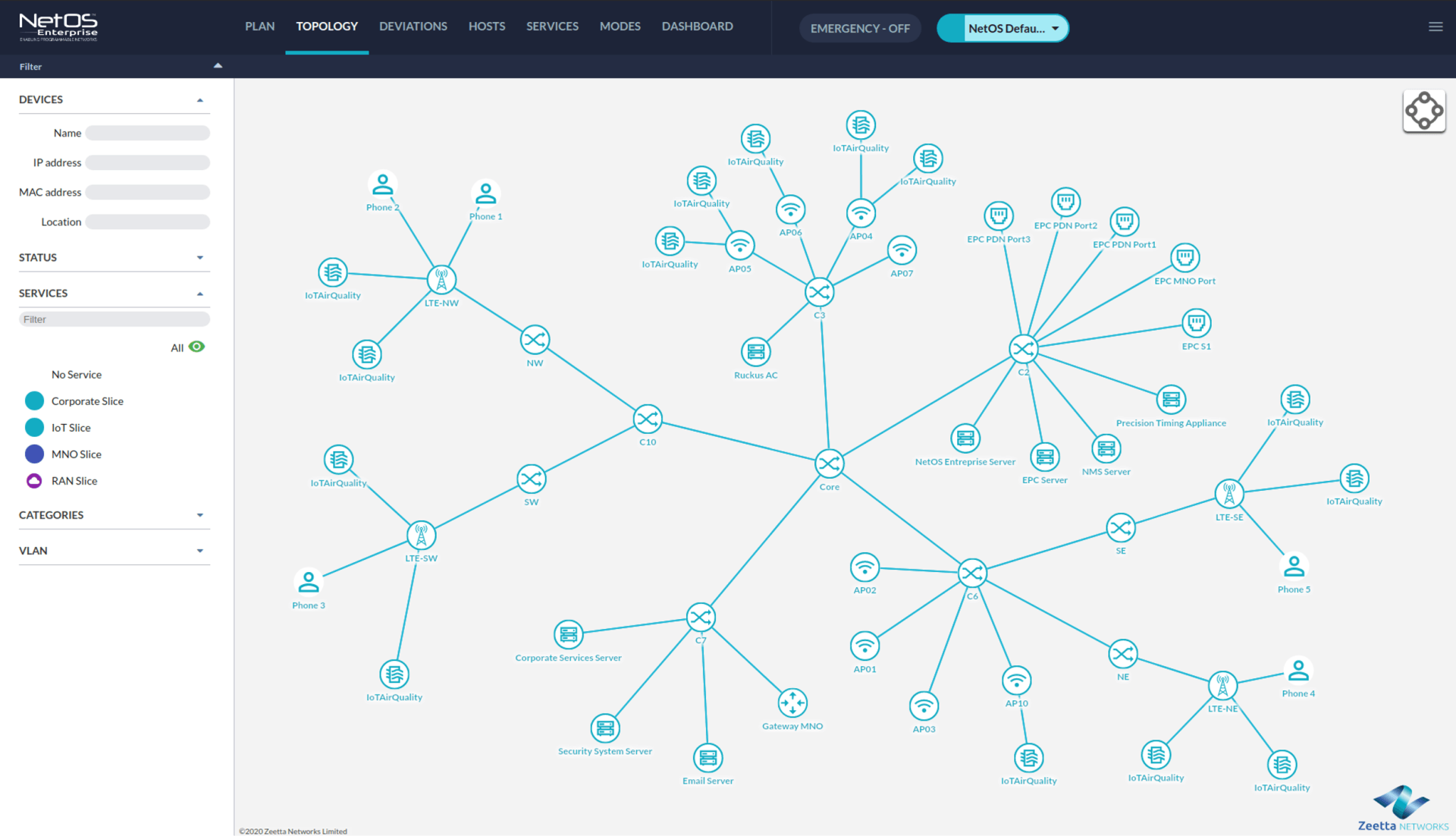

That’s not the only reason for the slow roll-out. “There’s an issue with mobile networks deploying 5G,” says Vassilis Seferidis, CEO of Zeetta Networks, a UK-based intelligent network automation company. 5G requires an even denser network of base stations compared to other mobile networks such as 4G and 3G. “They need to invest more money and that becomes impractical for them because they’re still deploying 4G,” Seferidis says. This means mobile networks are dragging their feet.

In the UK, Germany and elsewhere, one solution for the manufacturing industry is private networks. “All major industrial players like car manufacturers and chemical plant operators received licences for setting up self-administered 5G networks in their plants, for example BASF, Siemens, BOSCH, BMW, VW in Germany,” says Zühlke. “The next step will be getting experiences with this new technology. First, the ‘low hanging fruits’ will be collected, then the more complex and security critical applications will follow.”

Zeetta is leading a £9m UK government initiative – its biggest investment in 5G for manufacturing so far – that will set up a private 5G network at the National Composites Centre in Bristol. Other participants in the project include Siemens, Toshiba, and Telefonica. The project will test out new business cases for private 5G networks in industrial settings, including augmented and virtual reality to deliver training and improve design in manufacturing, the improvement and monitoring of industrial systems, and the tracking of assets across different sites – for example chemicals that must be kept at very precise temperatures for precise lengths of time.

Seferidis is bullish on the potential of this initiative and 5G private networks. “Now you can support what you weren’t able to support with wi-fi, and allow connectivity to devices or user groups that were not possible before,” he says. “You can deliver connectivity at a bespoke or customised level.” It’s still early days, but 5G evangelists see it as pivotal to ushering in the fourth industrial revolution.

14 Dec, 2020

5G-ENCODE is a pioneering project looking to make the benefits of 5G technology a reality for UK manufacturers. The project is one of the UK government’s biggest investments in 5G for manufacturing to date and has been set up to establish clear business cases and value propositions for the application of 5G technology in manufacturing. Led by Zeetta Networks, activity started in early 2020 and will run until March 2022. The key objective is to design and deliver a private 5G network within the National Composites Centre. This will be used to explore new business models and 5G technologies, including network slicing and splicing, within an industrial environment. Specifically, activity will focus on three areas: AR/VR to support design, manufacturing and training Monitoring and tracking of time sensitive assets Wireless real-time in-process monitoring and analytics These use cases will be sector agnostic and will be deployed across a range of industries enabling new business models and opportunities, streamlining operations and creating additional revenue streams. This is especially important as the nation navigates economic turbulence brought about by the Covid-19 pandemic.

by websitebuilder-hub

•

23 Oct, 2020

5G-ENCODE switches on the first phase of its network at the National Composites Centre. This will test existing technologies and provide a baseline against which the 5G network capabilities will be compared. The project will establish and test 5G use cases to make the benefits of 5G a reality for UK manufacturers. London, 22nd October 2020: Today, 5G-ENCODE, a pioneering project that aims to make the benefits of 5G a reality for UK manufacturers, announces the switch on of its Phase One Industrial Private 4G Network at the world leading National Composites Centre (NCC), to establish a baseline for existing technology. This comes ahead of its Phase Two Industrial Private 5G Network, which will go live in 2021. The Phase One 4G network has been designed and developed by leading partners, Zeetta Networks and the University of Bristol’s Smart Internet Lab, and installed at the National Composites Centre. It will be used to establish a baseline for existing cellular technologies, against which results from the private 5G network, which will be installed in Phase Two of the project, can be benchmarked. The goal is to prove the value of 5G for use case performance and user experience and demonstrate the extent to which businesses will get a real return on investment from deploying private cellular networks within manufacturing. 5G-ENCODE is part of the Department for Digital, Culture, Media and Sport’s (DCMS) 5G Testbeds and Trials Programme and is one of the UK government’s biggest investments in 5G for manufacturing to date. New technologies, particularly 5G, hold the key to unlocking significant benefits for manufacturers, including streamlining operations and increasing productivity. The project has been set up to establish clear business cases and value propositions for the application of 5G technology in manufacturing. The cellular network will be used to explore new business models and 5G technologies, including network slicing and splicing, within an industrial environment. Specifically, activity will focus on three areas: Augmented Reality / Virtual Reality (AR/VR) to support design, manufacturing and training. Monitoring and tracking of time sensitive assets. Wireless real-time in-process monitoring and analytics. In the Phase One 4G Network, the focus will be on testing the asset tracking and AR / VR use cases. Each use case will be tested and data gathered on network performance, user experience and business benefit realisation. This process will be repeated for the Phase Two 5G Network and the data between 4G and 5G will be compared and analysed. Vassilis Seferidis, co-founder and CEO at Zeetta Networks says: “Zeetta Networks is proud to be the leading partner for the 5G-ENCODE project. The use cases being explored will be integral to accelerating Industry 4.0. Phase One is just the beginning, and we’re confident that this project will be key to revitalising the UK’s manufacturing industry and safeguarding it against the next global recession”. Marc Funnell, Head of Digital, and Director of DETI, National Composites Centre, says: “As a world-class research centre, the NCC is delighted to be the industrial test bed for the 5G-ENCODE consortium of leading industrial innovators. Today’s announcement marks the start of this project delivering real-life impact through the development of specific use cases for the 5G-ENCODE and Digital Engineering Technology & Innovation (DETI). We look forward to testing and sharing the results”. Xavier Priem, Senior Research Fellow at Smart Internet Lab says: “Smart Internet Lab is proud to support and provide expertise to the 5G-ENCODE consortium. We are delighted to be working alongside communities, telecom and Industry 4.0 experts in this project by providing knowledge on 4G & 5G technologies on the delivery of use cases. Our work will be fundamental in introducing new capabilities into Industry 4.0 processes and systems which will provide more flexibility.” --ENDS-- About 5G-ENCODE 5G-ENCODE is a £9 million collaborative project aiming to develop clear business cases and value propositions for 5G applications in manufacturing. The project is partially funded by the Department for Digital, Culture, Media and Sport of the UK Government as part of its 5G Testbeds and Trials Programme. It is run by a consortium of nine partners: Zeetta Networks, National Composites Centre, Mativision, Plataine, Solvay, Toshiba, Telefonica, Siemens and the University of Bristol’s Smart Internet Lab. https://www.5gencode.com Download