Blog Layout

Plataine selected to partner in a UK Government funded, 5G based, advanced manufacturing project

Jun 23, 2020

March 10, 2020, Tel-Aviv, Israel – Plataine has been announced as one of 11 industry partners to join the UK Government’s 5G-ENCODE project that will deliver a private 5G network at the National Composites Centre in Bristol, UK. 5G-ENCODE will examine industrial use cases and value propositions for the practical application of 5G wireless technology to upgrade composite design and production processes at UK manufacturers – delivering radical productivity and efficiency improvements. To support the project, Plataine will implement its AI (Artificial Intelligence)-based Industrial IoT solution that allows full material and asset tracking, predictive alerts and optimized recommendations.

Plataine was selected due to its unique global experience at applying IIoT solutions to composites manufacturing processes, for customers as diverse as Airbus and Renault F1 Team. At the National Composites Centre, Plataine will implement its AI-based Digital Assistants, integrated with a locally deployed sensor network, to deliver comprehensive material shelf-life tracking, management and optimization capabilities. The solution will automatically track time-sensitive raw materials, predict remaining exposure time and optimally select the most appropriate material for each job at hand; minimizing waste and ensuring production deadlines are met, while maintaining full traceability of the products’ Digital Thread. In addition, automated real-time tool tracking ensures production schedules are no longer disrupted by lost tools, and AI-based Digital Assistants offer predictive quality alerts, actionable insights and real-time maintenance recommendations to staff.

Dr. Enrique Garcia, CTO at the NCC said: “As world-leaders in composite research, the NCC provides beyond state-of-the-art capabilities for industry. An industrial scale 5G test bed at the NCC will showcase a step change in security, reliability and connectivity, providing companies of all sizes a risk-free environment to evaluate and capitalise on the capabilities offered by 5G. The test bed is part our wider Digital Engineering strategy in the West of England which will form a national asset to catapult the application of digital technologies into the engineering sector. This programme affords us and our industrial partners a unique opportunity to collaborate with prominent experts in the telecommunication, digital and software industry. We are delighted to be a part of such a rare multi sectoral consortium.”

Avner Ben-Bassat, President and CEO of Plataine, adds: “The 5G-ENCODE project will apply 5G-enabled technologies to manufacturing, integrated with Plataine’s Digitization and AI solutions to improve efficiency with industrial systems management. Automating and optimizing manufacturing is absolutely at the core of Plataine’s offering, and we are very excited to be working on this ground-breaking project.”

About Plataine

Plataine is the leading provider of Industrial IoT and AI-based optimization solutions for advanced manufacturing. Plataine’s solutions provide intelligent, connected Digital Assistants for production floor management and staff, empowering manufacturers to make optimized decisions in real-time, every time. Plataine’s patent-protected technologies are used by leading manufacturers worldwide, including Airbus, GE, Renault F1® Team, IAI, Triumph, General Atomics, TPI Composites, AAT Composites and MT Aerospace. Plataine partners with Google Cloud, Siemens PLM, McKinsey & Company, TE Wire & Cable, VIRTEK, the AMRC with Boeing, the NCC, and CTC GmbH (an Airbus Company), to advance the ‘Factory of the Future’ worldwide. For this work, Plataine has received a Leadership Award from Frost & Sullivan and Innovation Awards from the JEC and CompositesUK organizations, as well as the Shanghai Society of Aeronautics (SSA). For more information, visit: www.plataine.com

About the NCC

The National Composites Centre (NCC) is a world-class research centre, where companies of any size and across industry sectors can access cutting-edge technology and specialist engineers. It is one of seven centres that form the High Value Manufacturing Catapult and focuses on accelerating the adoption of high-value, sustainable engineering solutions in composites, in order to stimulate growth, and enhance capability for the benefit of the UK. The NCC has over 350 composite specialists based at its Bristol facility and offers open-access to cutting-edge digital manufacturing technology for the design, and development of new composite products pulling through technology from the lab to large-scale production. Visit www.nccuk.com

14 Dec, 2020

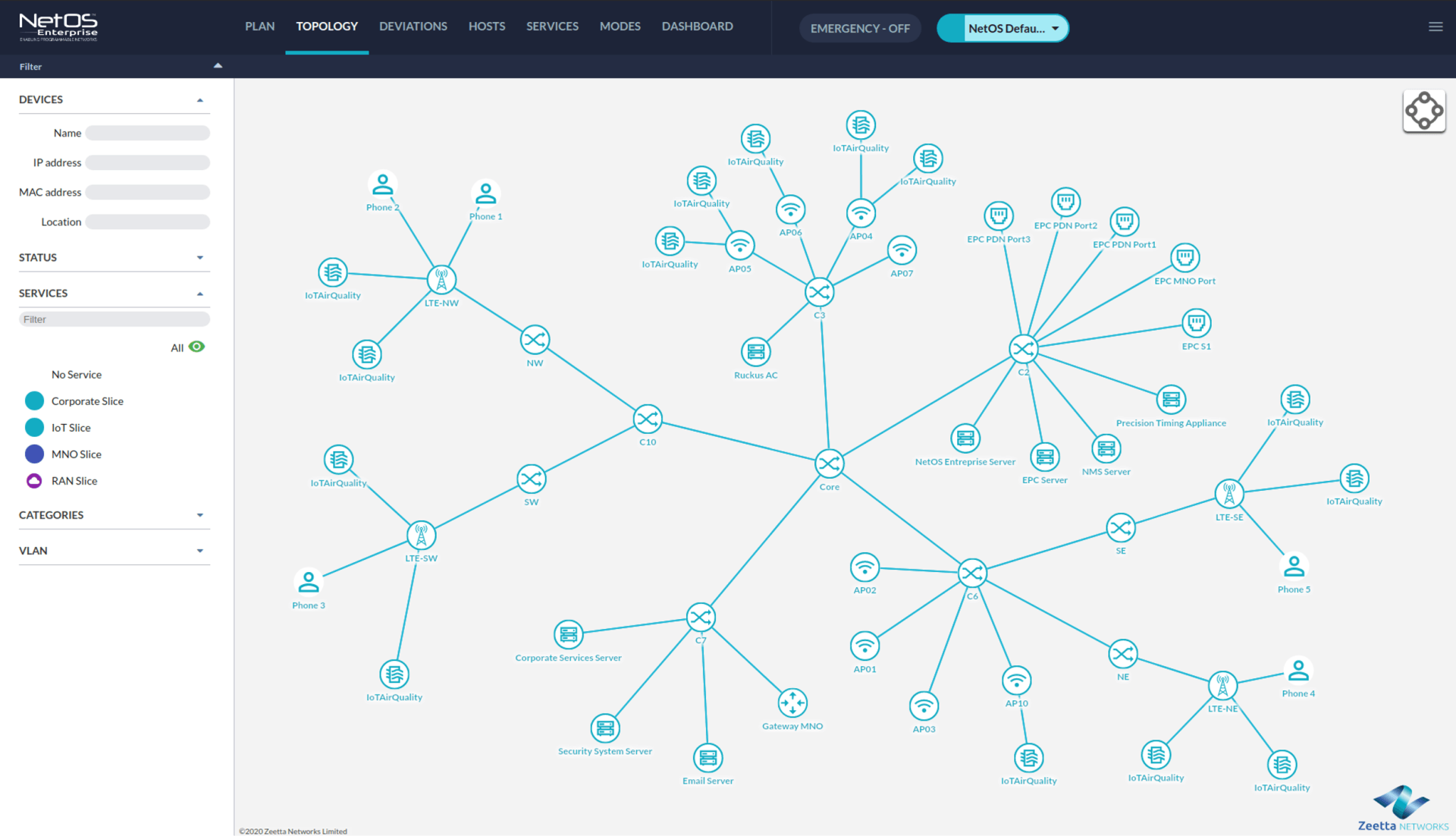

5G-ENCODE is a pioneering project looking to make the benefits of 5G technology a reality for UK manufacturers. The project is one of the UK government’s biggest investments in 5G for manufacturing to date and has been set up to establish clear business cases and value propositions for the application of 5G technology in manufacturing. Led by Zeetta Networks, activity started in early 2020 and will run until March 2022. The key objective is to design and deliver a private 5G network within the National Composites Centre. This will be used to explore new business models and 5G technologies, including network slicing and splicing, within an industrial environment. Specifically, activity will focus on three areas: AR/VR to support design, manufacturing and training Monitoring and tracking of time sensitive assets Wireless real-time in-process monitoring and analytics These use cases will be sector agnostic and will be deployed across a range of industries enabling new business models and opportunities, streamlining operations and creating additional revenue streams. This is especially important as the nation navigates economic turbulence brought about by the Covid-19 pandemic.

by websitebuilder-hub

•

23 Oct, 2020

5G-ENCODE switches on the first phase of its network at the National Composites Centre. This will test existing technologies and provide a baseline against which the 5G network capabilities will be compared. The project will establish and test 5G use cases to make the benefits of 5G a reality for UK manufacturers. London, 22nd October 2020: Today, 5G-ENCODE, a pioneering project that aims to make the benefits of 5G a reality for UK manufacturers, announces the switch on of its Phase One Industrial Private 4G Network at the world leading National Composites Centre (NCC), to establish a baseline for existing technology. This comes ahead of its Phase Two Industrial Private 5G Network, which will go live in 2021. The Phase One 4G network has been designed and developed by leading partners, Zeetta Networks and the University of Bristol’s Smart Internet Lab, and installed at the National Composites Centre. It will be used to establish a baseline for existing cellular technologies, against which results from the private 5G network, which will be installed in Phase Two of the project, can be benchmarked. The goal is to prove the value of 5G for use case performance and user experience and demonstrate the extent to which businesses will get a real return on investment from deploying private cellular networks within manufacturing. 5G-ENCODE is part of the Department for Digital, Culture, Media and Sport’s (DCMS) 5G Testbeds and Trials Programme and is one of the UK government’s biggest investments in 5G for manufacturing to date. New technologies, particularly 5G, hold the key to unlocking significant benefits for manufacturers, including streamlining operations and increasing productivity. The project has been set up to establish clear business cases and value propositions for the application of 5G technology in manufacturing. The cellular network will be used to explore new business models and 5G technologies, including network slicing and splicing, within an industrial environment. Specifically, activity will focus on three areas: Augmented Reality / Virtual Reality (AR/VR) to support design, manufacturing and training. Monitoring and tracking of time sensitive assets. Wireless real-time in-process monitoring and analytics. In the Phase One 4G Network, the focus will be on testing the asset tracking and AR / VR use cases. Each use case will be tested and data gathered on network performance, user experience and business benefit realisation. This process will be repeated for the Phase Two 5G Network and the data between 4G and 5G will be compared and analysed. Vassilis Seferidis, co-founder and CEO at Zeetta Networks says: “Zeetta Networks is proud to be the leading partner for the 5G-ENCODE project. The use cases being explored will be integral to accelerating Industry 4.0. Phase One is just the beginning, and we’re confident that this project will be key to revitalising the UK’s manufacturing industry and safeguarding it against the next global recession”. Marc Funnell, Head of Digital, and Director of DETI, National Composites Centre, says: “As a world-class research centre, the NCC is delighted to be the industrial test bed for the 5G-ENCODE consortium of leading industrial innovators. Today’s announcement marks the start of this project delivering real-life impact through the development of specific use cases for the 5G-ENCODE and Digital Engineering Technology & Innovation (DETI). We look forward to testing and sharing the results”. Xavier Priem, Senior Research Fellow at Smart Internet Lab says: “Smart Internet Lab is proud to support and provide expertise to the 5G-ENCODE consortium. We are delighted to be working alongside communities, telecom and Industry 4.0 experts in this project by providing knowledge on 4G & 5G technologies on the delivery of use cases. Our work will be fundamental in introducing new capabilities into Industry 4.0 processes and systems which will provide more flexibility.” --ENDS-- About 5G-ENCODE 5G-ENCODE is a £9 million collaborative project aiming to develop clear business cases and value propositions for 5G applications in manufacturing. The project is partially funded by the Department for Digital, Culture, Media and Sport of the UK Government as part of its 5G Testbeds and Trials Programme. It is run by a consortium of nine partners: Zeetta Networks, National Composites Centre, Mativision, Plataine, Solvay, Toshiba, Telefonica, Siemens and the University of Bristol’s Smart Internet Lab. https://www.5gencode.com Download